System solution objectives

The detection equipment of the company covers an area of about 6M X 4M, which will provide the necessary coordinate measuring machines and equipment for the automation system. Combined with the robot and its automatic control system, the automatic detection of the electrode can be realized on the modular system platform of Modebao, so as to reduce the labor intensity of personnel and improve the measurement efficiency.And the information flow of the electrode can be effectively integrated with the RFID system to ensure the information fluency and traceability of the detection link.

CMM automatic detection

After identifying the RFID chip, the system will automatically match and obtain the program corresponding to the detected electrode, and automatically remotely start the machine tool for electrode detection;After the CMM test is completed, the system will automatically judge whether the electrode test result is OK or NG.

Equipment

Flexible assembly workshop

- Automatic copper foil welding, robot feeding, high motion precision, high efficiency, high flexibility, fully automated and modern production line;

- Automatic assembly line and automatic reflux of the vehicle can realize free transportation of products, simplify the transportation track of products and improve the working tempo.

- Automatic dispensing, high precision control system, intelligent operation, fast speed, high precision;

- The integrated production line of automatic clamping and disassembling realizes automatic pressing, automatic clamping, efficient and fast disassembling.

Automated accessories production workshop

- The system adopts programmable controller (PLC) as the core, which has high precision and good stability.It has the advantages of strong versatility, wide adaptability and strong anti-jamming ability.

- Intelligent control laminating system, with high precision vision system, to achieve fast and efficient laminating accessories;

- The system is simple to operate, with manual, semi-automatic, automatic three production modes;

- The new man-machine control interface, the formula process can be adjusted and set at any time by the management personnel carrying the password.

Automatic radium carving workshop

- Six axis robot automatic loading and unloading, high efficiency, high precision;

- With its own turnover function, can achieve a multiple surface radium carving;

- Powerful ventilation system makes the workshop clean and tidy without peculiar smell.

Introduction of Injection Molding Department

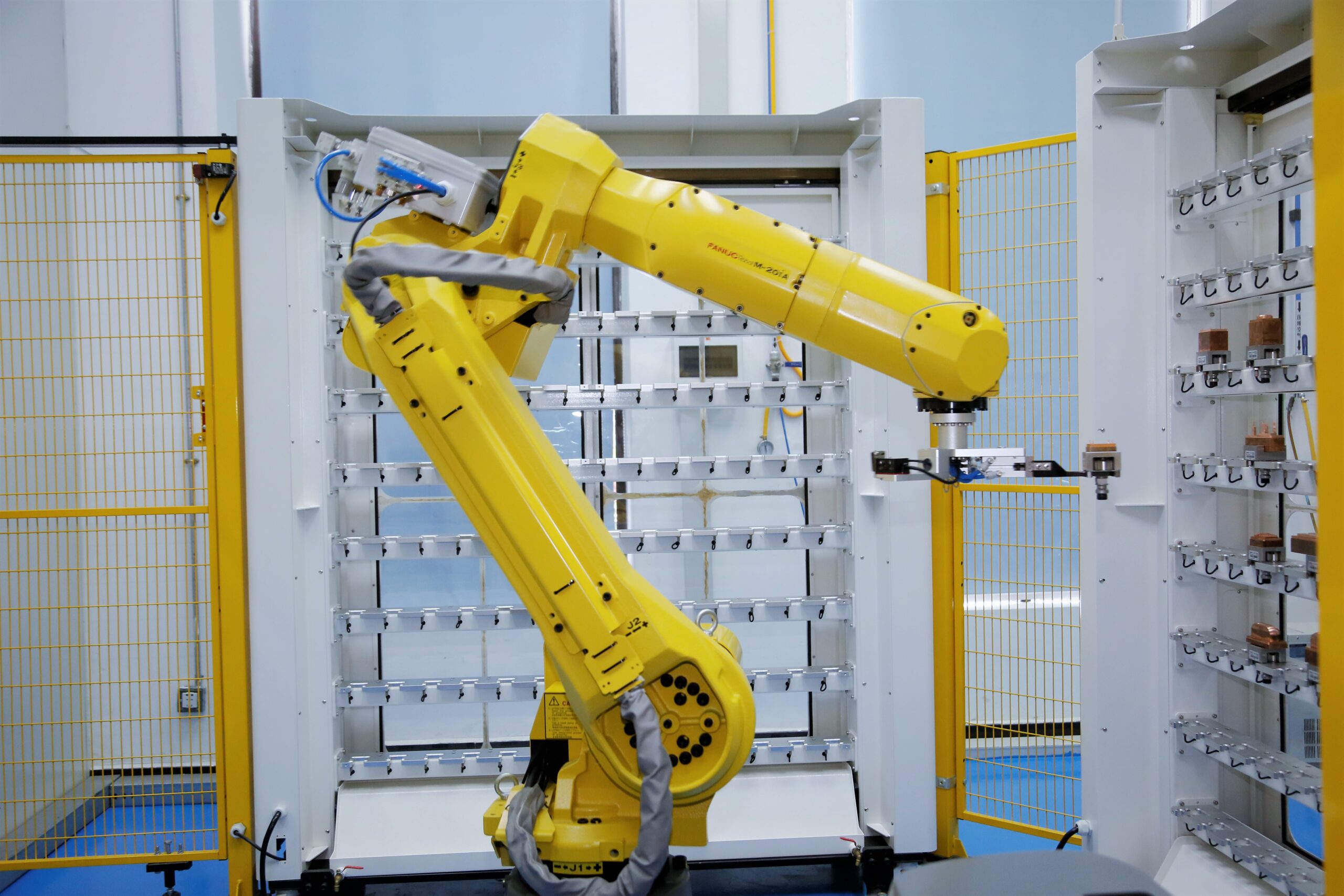

The injection molding department is divided into mobile phone shell production workshop, IOT product production workshop and dust-free workshop. It owns 291 sets of injection molding machines of world famous brands such as FANUC, SUMITOMO, TOSHA, DEMAG and HAITIAN.

Introduction of automatic radium engraving

After injection molding, the manipulator takes out the product from the mold and places the product to the transition fixture for positioning. Then the robot takes out the product and places it on the radium engraving positioning fixture, and starts the radium engraving machine to process the product. After the radium engraving is completed, the robot carries the product to the conveyor belt for full inspection and shipment.

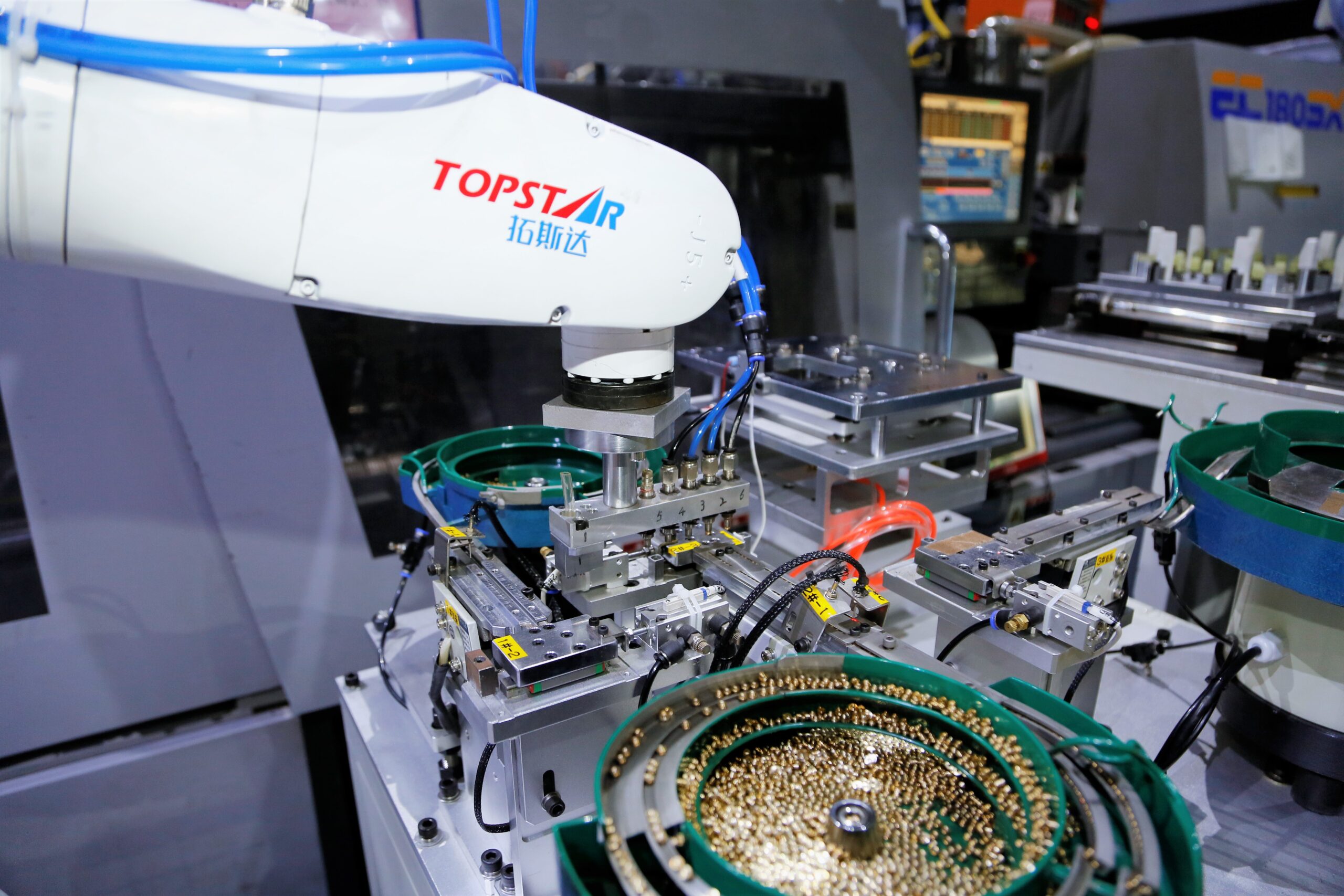

Introduction of automatic nut implantation

Robot with automatic nut machine and manipulator, complete automatic nut implantation;In advance, the nut is put into the circular vibrator, and after starting the vibration plate, the nut is transmitted in the circular vibrator track.In this process, the circular vibrator can accurately screen the nuts, and the nuts whose orientation does not meet the requirements of planting will be shaken off, and the qualified nuts will successfully enter the linear vibrator through the circular vibrator.After the nuts are accurately positioned by linear vibrator, the robot uses a special fixture to draw the nuts, and then places the nuts of different shapes on the positioning fixture according to the requirements of implantation, waiting for the manipulator of the injection molding machine to take them.

Introduction of Full automatic plate blanking

This technology is widely used in a number of projects, and can be linked with a variety of processing technology;Manipulator will take out the product, move to the automatic shaping machine;After the feeding is completed, the shaping machine starts, and multiple signals are linked to control each part to complete the automatic shaping process.After receiving the shaping signal, the robot will move the product to the loading area and put it into the blister box in turn.After placing the layer blister box, the feeding module is controlled by PLC to descend;Then, the feeding module and the transverse moving module cooperate with the action, the empty blister is stacked on the full blister waiting for feeding;After the cyclic action, the number of stack layers of the blister reaches the set value, and the blanking module moves down;After the drop in place, the conveyor belt will send the product to the discharge level, and the feeding module will return to the initial position to wait for loading.

Automatic milling nozzle

One robot can handle the products produced by two injection molding machines. A manipulator of the injection molding machine will remove the products and move them to the processing side.After the robot is in place, the product will be successfully picked up and transported to 1#CNC;When starting 1#CNC, the robot moves to the manipulator of B injection molding machine to pick up the products of B injection molding machine.Put the product into 2#CNC positioning fixture and start 2#CNC, and take away the finished product of A injection molding machine in 1#CNC;After the product is put into the 1# conveyor belt, the robot returns to the standby position of the injection molding machine A and waits for the next cycle.

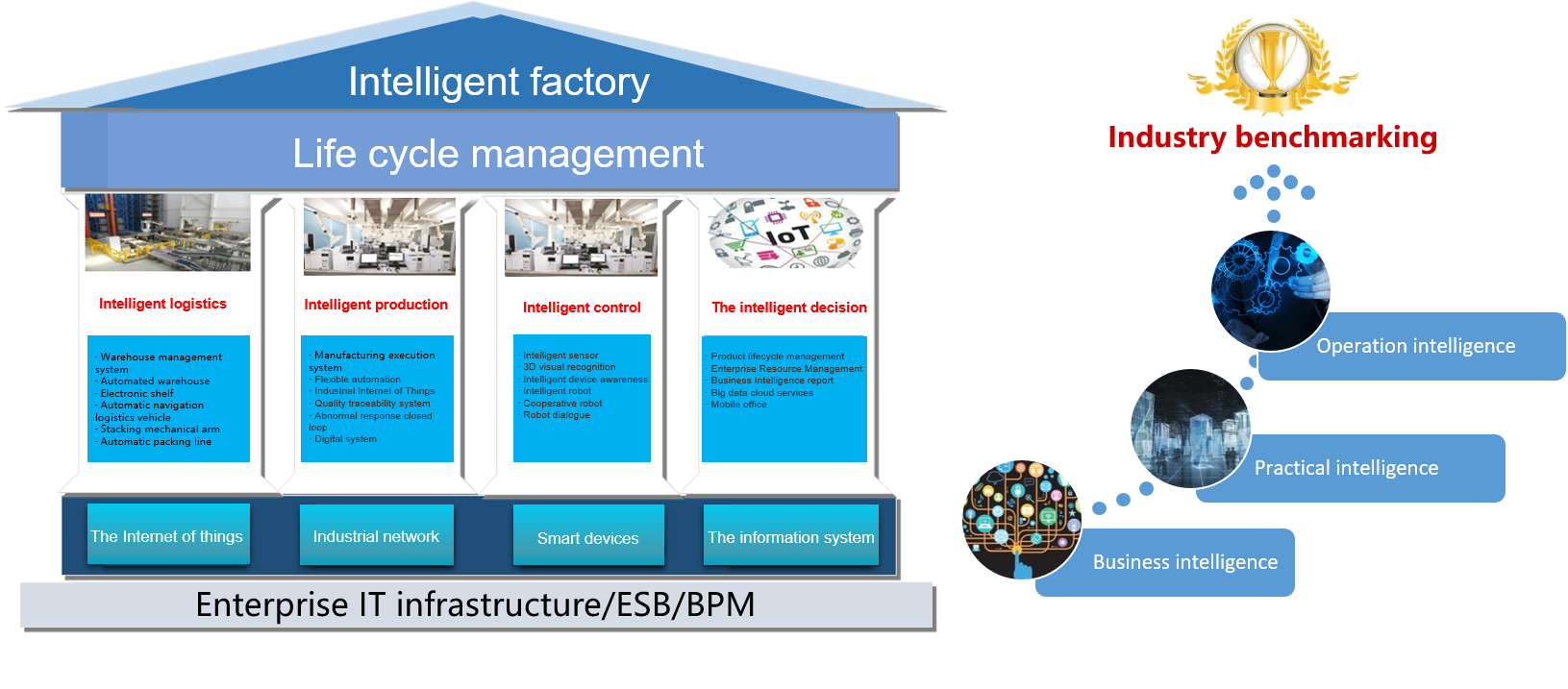

Intelligent manufacturing informatization

Intelligent manufacturing information system

Vertical up: unified data source to realize unified management and distributed application of multiple regions and multiple factories

Horizontal up: multiple functional departments cooperate in manufacturing to drive the overall business process.