mold

We mainly produce mobile phone case, tablet computer case, digital battery case, mobile power supply case, sweeper case, handheld vacuum cleaner case, Bluetooth headset case, smart home case mold and so on

-

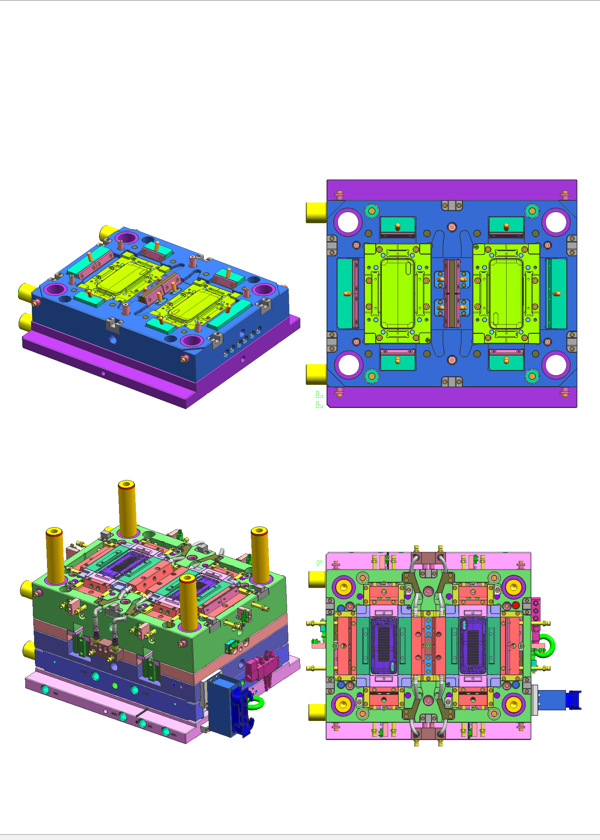

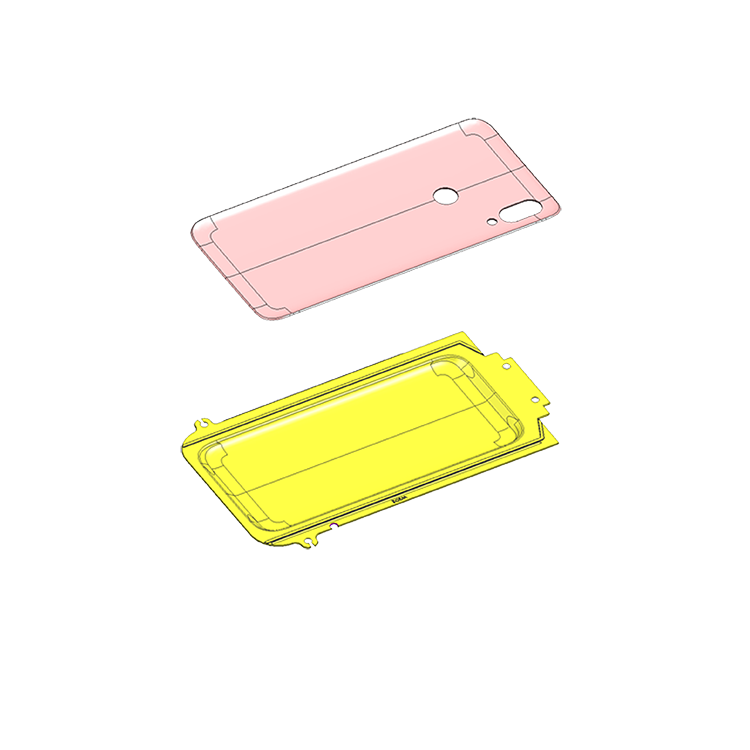

Mobile phone shell mold

Mobile phone shell mold- Two – plate mold with hot runner system point gate

- No cold material is produced, and the appearance of the product is required to be high (grain surface).

- The shape is complex and the mold structure is relatively simple

- Automated production requires high efficiency

-

Tablet Mold

Tablet Mold- Three plate mold with hot runner system to cold runner point gate

- The product requires high precision

- The shape is complex and the mold structure is relatively simple

- Automated production requires high efficiency

-

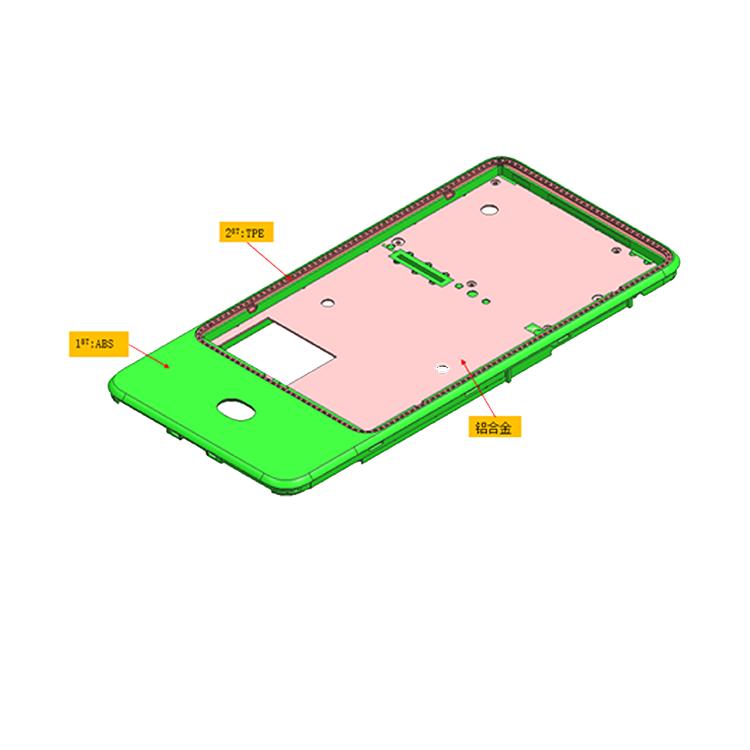

IOT mold

IOT mold- Three plate mold with hot runner system to cold runner point gate

- High requirements for product appearance surface (specular or mirror)

- The mold structure is compact and complex

- Automated production requires high efficiency

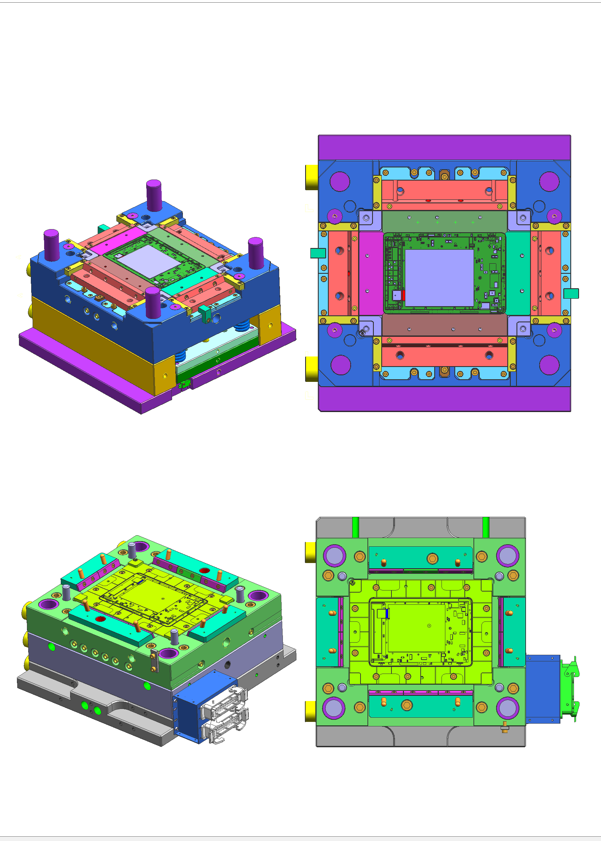

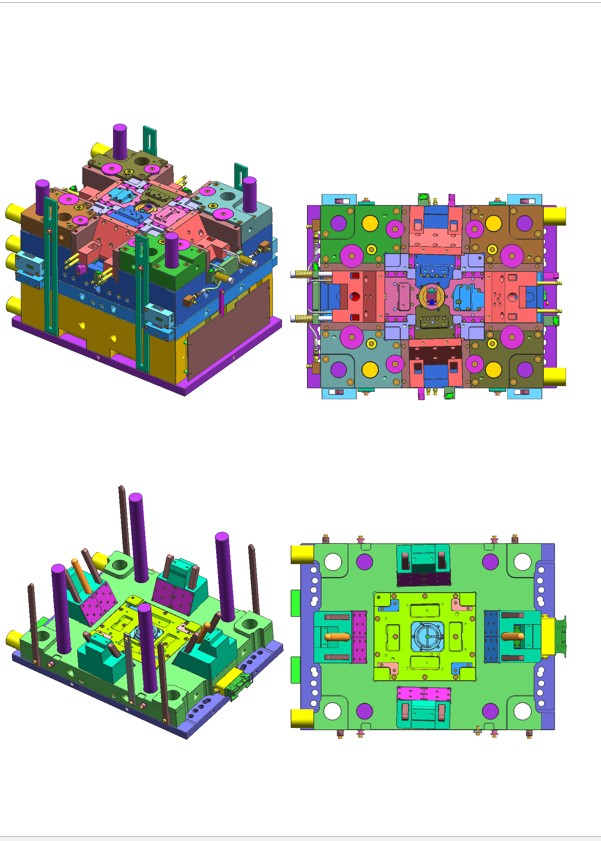

Precision mold type

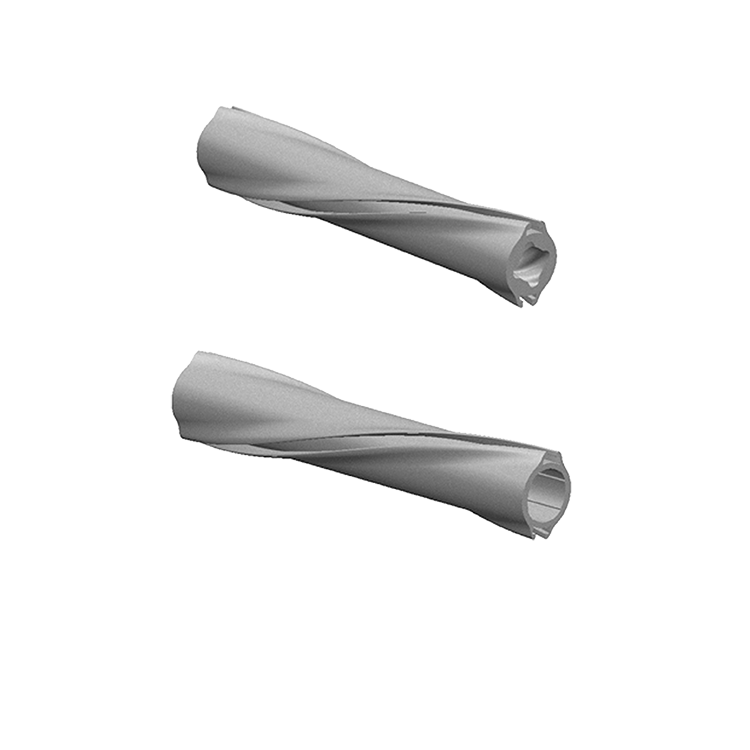

Single color + double color mold, core pulling mold, screw mold, Reverse mold, compression + mirror mold, multi-cavity mold -32 cavities

-

Rotating shaft mold

-

compression mold

-

two-color mold +Insert mold

-

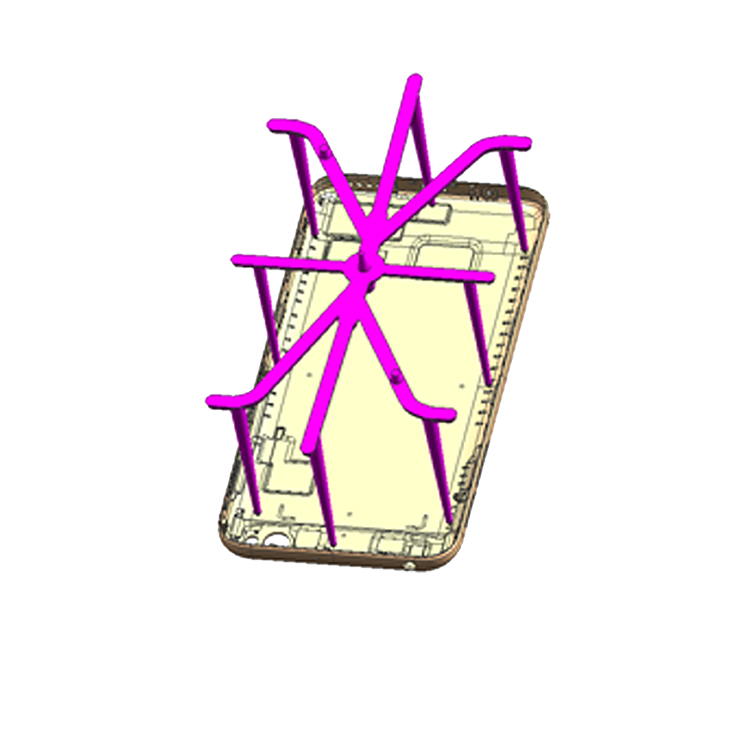

complex mechanism mold 1

-

complex mechanism mold 2

-

Reverse mold

Main process

Injection molding

- Injection molding core technology:

- 1. In-mold molding

- 2, thin wall molding

- 3, transparent high light molding

- 4, transparent compression molding

- 5. Two-color injection molding

- 6. Automatic insert molding technology

CNC

- Ability:

- 1. Before/after painting

- 2. Die casting or plAbility:roducts

- 3. The Mic hole

Spraying

- Ability:

- 1. UV, PU, light touch

- 2. Matte/Highlight

- 3. 3D/gradient/multi-layer spray

NCVM

- Ability:

- 1. The highlights

- 2. The gradient

Screen printing

- Ability:

- 1. UV, PU, light touch

- 2. Matte/Highlight

- 3. 3D/gradient/multi-layer spray

Polishing

- Ability:

- 1. Product parting line, burr

- 2. Lines, angles and surfaces

Radium vulture

- Ability:

- 1. Before/after painting

- 2. Die casting or plastic products

Dispensing

- Ability:

- 1. The hot melt adhesive

- 2. AB glue

- 3. Conductive adhesive

Assembly

- Ability:

- 1. Automatic segment difference check

- 2.Self implant screw

- 3.3d dispensing

- 4.100% of the CCD inspection

- 5.Hot pressing, laser, ultrasonic welding and so on

Equipment

Injection molding machine

Injection molding machines, the tonnage range is 50T-1200T, the main brands: FANUC, Sumitomo, Toshiba, etc

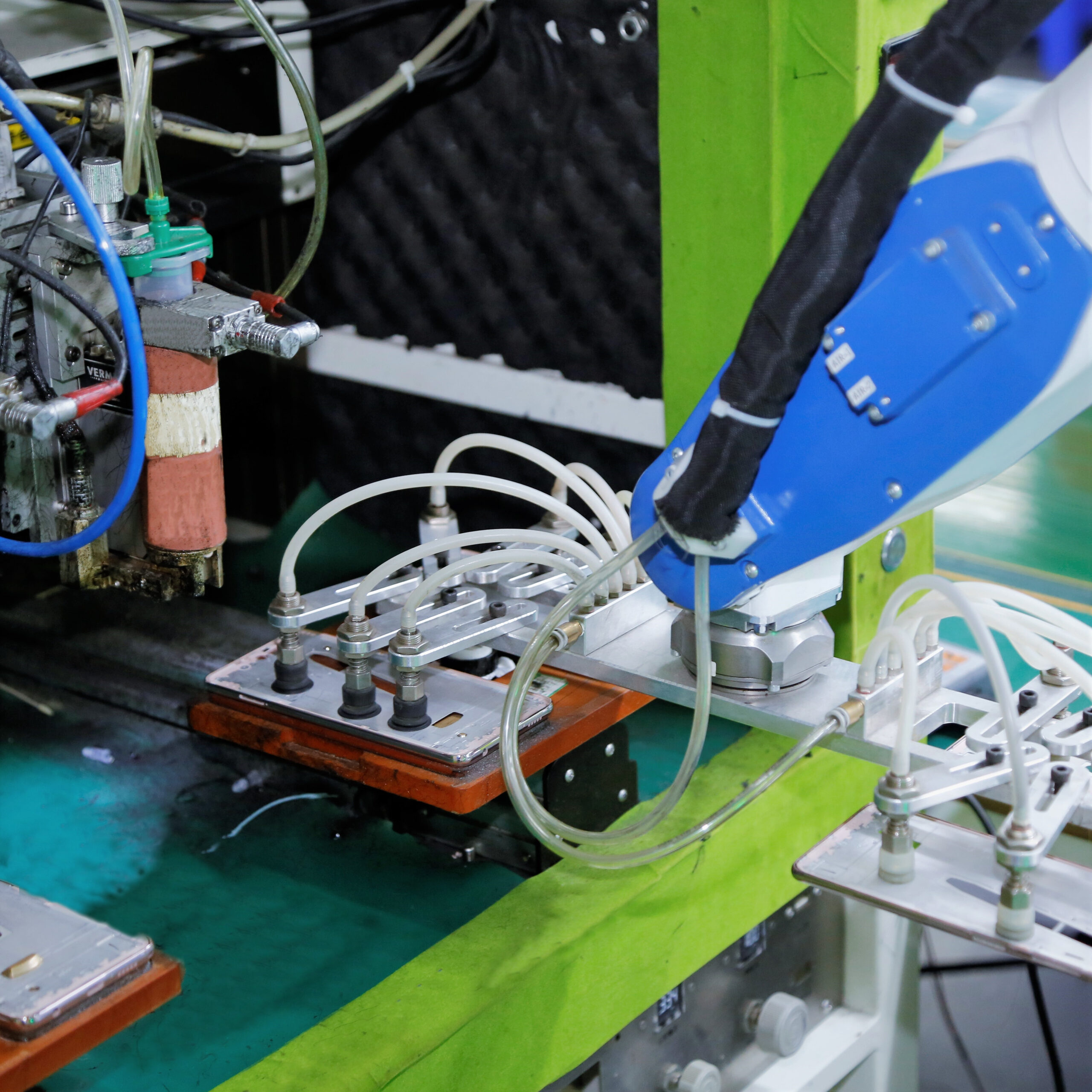

Fully automatic machine

1, Automatic feeding + plate loading

2, Automatic shaping + electric inspection integration

3, Automatic radium carving + ultrasonic cutting gate

4, Metal + nut automatic implantation

5, Dispensing + copper welding

6. Fully automatic radium carving

7, Automatic detection

8. Collaborative production of human and robot

The production workshop

1. Mold processing center

2. Injection molding workshop

3. Spraying workshop

4. CNC workshop

5. Assembly workshop

Full automatic production assembly line

1. Automatic accessories laminating

2. Automatic copper sheet welding

3. Automatic dispensing, pressure disassembly clip

-

MOBILE PHONE & TABLET

-

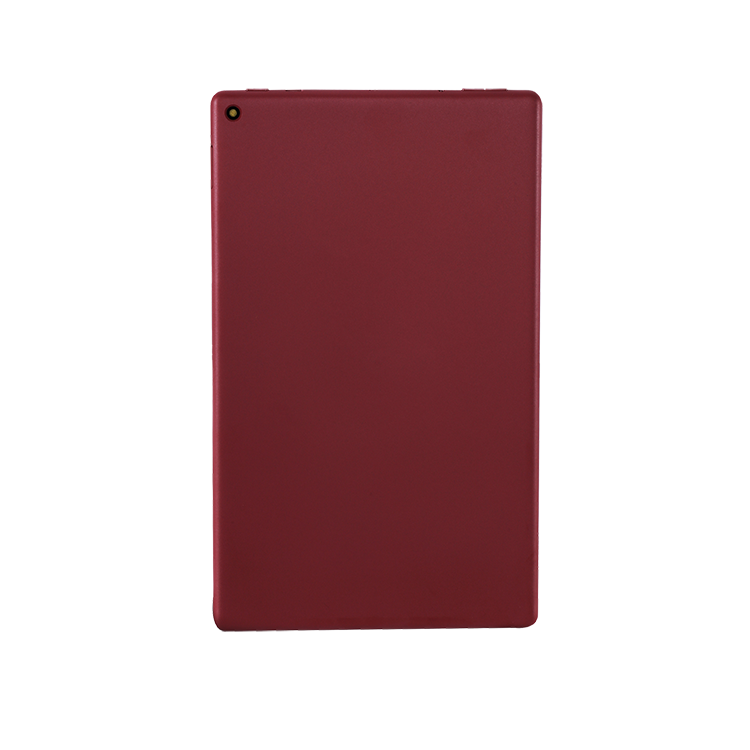

Precision injection molding parts of 10 inch tablet computer

-

Fine engraved textured gradient battery cover

-

Three – proof mobile phone precision plastic parts

-

-

IOT

-

TWS headphones

-

The silicone strap

-

Intelligent Home product

-

-

NEW PRODUCTS

-

IMT process

-

Composite plate

-

SIMD process

-